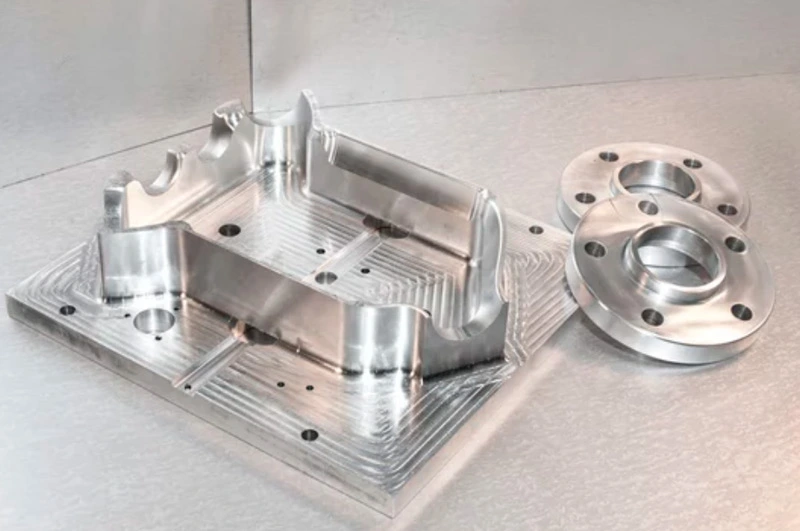

Material Options

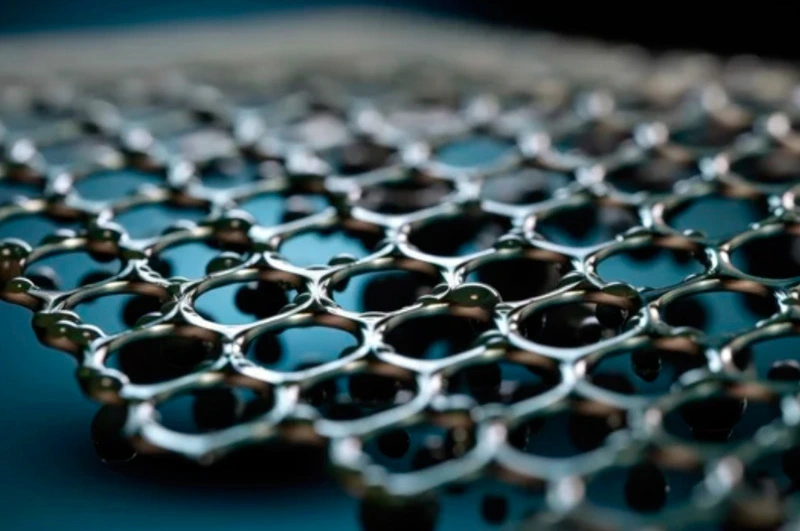

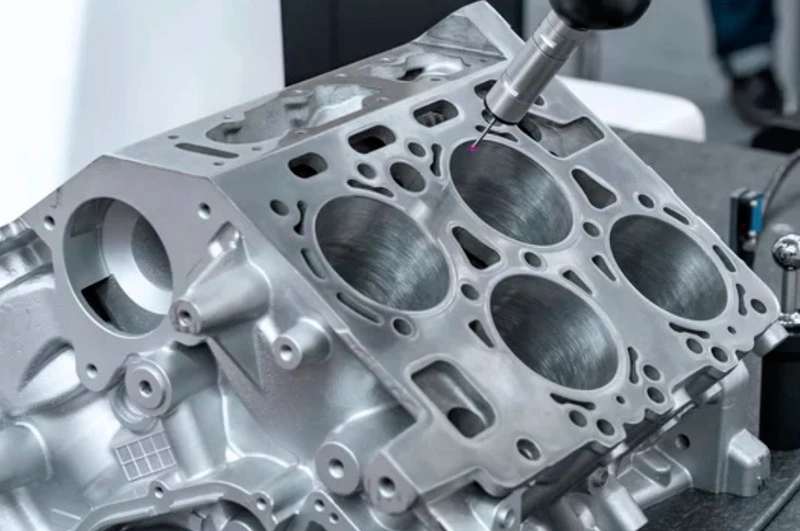

The selection of materials within Fine Precision's production services presents a multitude of advantages tailored to specific industries. From the versatility of plastics that enable intricate designs and lightweight applications to the durability and strength of metals suited for aerospace and automotive components, each material choice is strategically aligned with its industry's demands. Precision casting materials, including aluminum and stainless steel, offer high dimensional accuracy and mechanical properties, while sheet metal fabrication materials such as steel and aluminum enable precise cuts and complex shapes. Rapid prototyping materials like plastics, metals, and composites empower designers to swiftly evaluate designs before production. By leveraging these material advantages, Fine Precision ensures the excellence and precision demanded by diverse industries.

English

English