Expert CNC milling and turning services for rapid prototyping and low-volume production. Our precision CNC milling machining secvices delivers custom parts fast with any material. Get an instant quote today.

Accelerate product development with our fast, affordable CNC milling prototyping. We provide precision machining for custom prototypes in any material and quantity. Get instant quotes and rapid turnaround.

Our expert CNC milling machine services delivers custom machined parts fast in low volumes. With precision technology and rapid turnaround, we manufacture quality components from any material. Get instant quotes of CNC mill price for your project now.

The choice of surface finish depends on factors like the intended use of the part, aesthetics, functionality, and the material being used. At Neway, we offer various surface finish options to match your specific CNC milling project requirements.

When it comes to producing metal machined parts, surface finishes play a crucial role in determining the final quality and functionality of the components. They can enhance performance, finish color, and even improve accuracy.

Electroplating provides several advantages, including enhanced corrosion resistance, improved wear resistance, and an aesthetically pleasing appearance.

Anodizing involves creating a controlled oxide layer on the surface of the metal through an electrochemical process. Anodized surfaces are corrosion-resistant, offer improved adhesion for paint and adhesives, and can be dyed in various colors for aesthetic purposes.

Passivation is a process used mainly for stainless steel parts. It removes free iron and other contaminants from the surface, creating a passive oxide layer that enhances corrosion resistance.

Powder coating is a dry finishing process where a fine powder is electrostatically applied to a metal part and then cured in an oven. It results in a durable, attractive finish resistant to chipping, scratching, and fading.

CNC milling is used to create engine parts, transmission components, chassis parts, and intricate molds for automotive manufacturing.

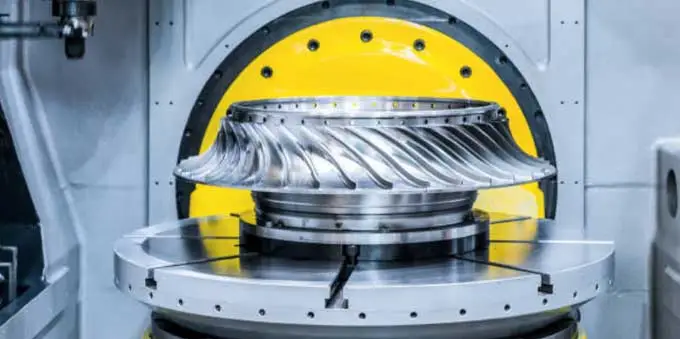

CNC milling produces aircraft structural components, engine parts, and complex prototypes with high precision.

Circuit boards, connectors, housings, and other electronic components are fabricated using CNC milling for accuracy and consistency.

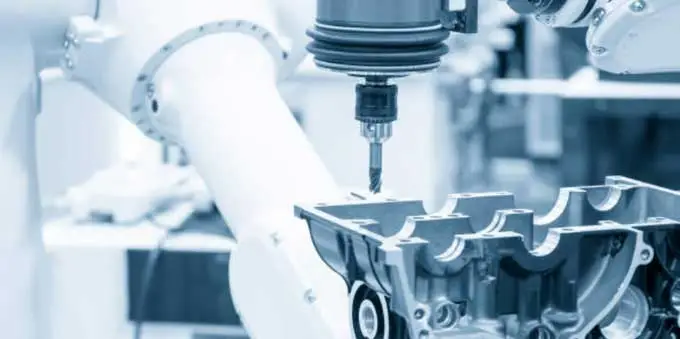

CNC milling involves using computer-controlled machines to remove material from a workpiece, creating precise shapes and features. Tools rotate and move along multiple axes to achieve desired designs.

CNC milling uses automated controls for precise and efficient machining, while manual milling relies on human operation and is typically slower and less accurate.

Our arsenal includes vertical machining centers, horizontal machining centers, and 5-axis machining centers, enabling us to tackle a wide range of projects.

We offer high-precision machining with tight tolerances, intricate geometries, and a variety of materials, from metals to plastics. Our advanced machinery ensures efficient production and exceptional quality.