CNC prototyping delivers fast turnaround times, allowing you to quickly iterate through multiple design versions. The automated machining process enables building parts in hours/days rather than weeks.

Precision CNC machines provide tight tolerances down to ±0.005 inches or less. Parts match the 3D CAD model dimensions and operate as designed for concept validation.

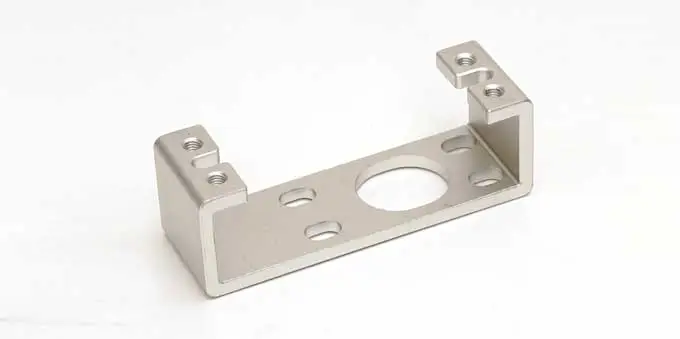

CNC can handle plastics, metals, foam, wood, and more. It supports complex geometries and can make small batches with different materials. The process is easily adjustable for design changes.

Achieve optimal function and aesthetics with our variety of CNC prototyping surface finishes. From raw to polished looks, we can match your custom prototype parts to specified textures and appearances. Evaluate designs before full production.

| Surface Finish | Description | Application |

| Smooth Finish | Clean, polished appearance | Aesthetics, consumer products |

| Matte Finish | Non-reflective, satin-like surface | Functional parts, reduced glare |

| Textured Finish | Patterns or textures for improved grip | Handles, tooling grips |

| Polished Finish | Mirror-like, highly reflective surface | Decorative components, high-end products |

| Brushed Finish | Uniform parallel lines for distinctive look | Decorative components, architectural details |

| Anodized Finish | Colored, corrosion-resistant oxide layer | Aerospace, electronics, consumer products |

| Bead-Blasted Finish | Uniform matte appearance through particle blasting | Medical devices, automotive components |

| Etched Finish | Patterns or text created through chemical/laser etching | Branding, labeling, personalization |

| Powder Coated Finish | Durable and decorative coating application | Outdoor components, machinery parts |

| Painted Finish | Various colors and textures applied with paint | Custom color requirements, artistic applications |

CNC prototyping rapidly validates automotive components like intake manifolds, pistons, and transmission parts. Machined prototypes test form, fit, and function before full auto production.

For consumer products, CNC milled prototypes enable testing of ergonomics, feel, and durability prior to manufacturing. Useful for sporting goods, electronics, and appliances.

Lightweight aerospace parts like airframe and engine components are prototyped with CNC machining. Testing verifies strength, fatigue resistance, and high precision before flight.

CNC prototyping enables fast fabrication of highly accurate parts, allowing for rapid design validation and testing before committing to full production.

Lost-wax casting involves sculpting a wax model, molding and casting it, then melting the wax out. CNC prototyping uses automated machining to precisely cut parts from raw material like metal or plastic.