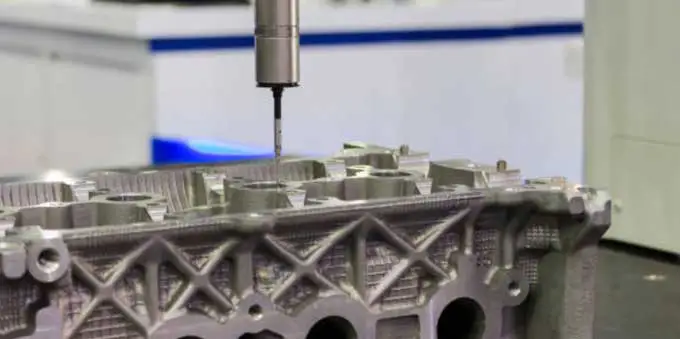

Intricate shapes, embosses, and textures can be easily reproduced in die cast parts of our die casting services.

High pressure die casting is highly efficient for medium to high volume production thanks to reusable molds.

Die cast parts of our die casting industry can obtain very smooth surface finishes without secondary machining required.

Die casting alloys of our die casting factory like aluminum and magnesium provide excellent strength-to-weight ratios.

Die-cast components often undergo surface treatments to enhance their appearance, durability, and functionality. The choice of surface treatment depends on the desired appearance, functionality, and material of the die-cast component.

| Surface Treatment | Description | Benefits | Applications |

| Painting | Applying coatings for protection and aesthetics. | Versatile colors, corrosion resistance. | Automotive parts, consumer goods. |

| Anodizing | Electrochemical process forming a protective oxide layer on aluminum. | Enhanced corrosion resistance, coloring options. | Aerospace components, electronics. |

| Plating | Electroplating with metals for aesthetics and corrosion resistance. | Aesthetic appeal, improved durability. | Decorative items, hardware. |

| Powder Coating | Applying dry powder and curing for a durable finish. | Even coating, scratch resistance. | Appliances, outdoor equipment. |

| Polishing | Mechanical polishing for a reflective and smooth finish. | Improved aesthetics, enhanced reflectivity. | Decorative items, automotive parts. |

| Brushing | Creating brushed or textured finishes. | Unique texture, hides scratches. | Architectural components, consumer goods. |

| Shot Blasting | Propelling abrasives for uniform texture and cleaning. | Matte texture, removes surface imperfections. | Automotive parts, machinery components. |

| Chemical Etching | Creating patterns or textures using chemicals. | Custom designs, intricate patterns. | Jewelry, decorative items. |

| E-Coating | Immersing in a paint bath with electric current for even coating. | Uniform coverage, corrosion resistance. | Automotive components, industrial parts. |

| Tumbling | Placing in a rotating drum with abrasive media for smoothing. | Even surface finish, deburring. | Hardware, small components. |

| Laser Etching | Engraving designs or text using laser technology. | Precise engraving, customization. | Electronic components, medical devices. |

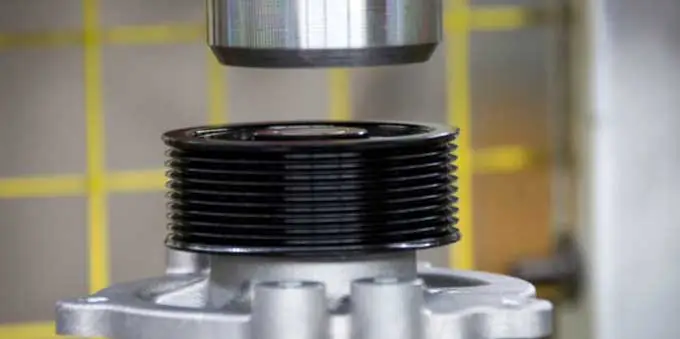

Manufacturing engine components, transmission parts, structural components, and decorative elements.

Producing housings for electronic devices, connectors, heat sinks, and intricate components.

Creating lightweight and strong components for aircraft engines, structural parts, and aerospace equipment.

Molten metal injected into mold under pressure, solidifies, and part is ejected. Precise and efficient for complex metal components.

Die Casting Applications: Used for intricate parts in automotive, electronics, aerospace, etc., due to high precision, tight tolerances, and smooth surfaces.

Die casting offers precision, smooth finishes, and speed with specific molds. Normal casting uses sand molds, suitable for diverse materials and shapes but with less precision.