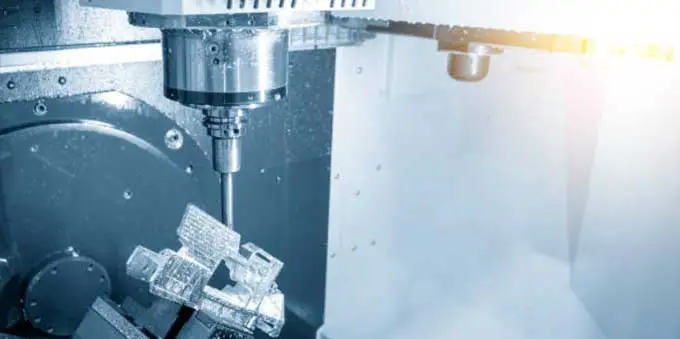

The additional axes provide greater tool tip access to machine challenging internal geometries and deep contours.

Simultaneous 5 axis motion ensures superior part geometric accuracy and repeatability even over long production runs.

5 axis capabilities allow complete parts to be machined in a single setup, reducing fixture requirements and manufacturing times.

5 axis machining enables the production of highly complex parts with intricately contoured surfaces not possible with 3 axis machines.

Our 5 axis CNC machining not only delivers complex geometries but also expert surface finishing options. From precision engraving and textures to polishing, plating, and more, we provide custom contoured parts with the surface finish your application requires.

| Surface Finish | Description | Application |

| Smooth Finish | Clean, polished appearance | Aesthetics, consumer products |

| Matte Finish | Non-reflective, satin-like surface | Functional parts, reduced glare |

| Textured Finish | Patterns or textures for improved grip | Handles, tooling grips |

| Polished Finish | Mirror-like, highly reflective surface | Decorative components, high-end products |

| Brushed Finish | Uniform parallel lines for distinctive look | Decorative components, architectural details |

| Anodized Finish | Colored, corrosion-resistant oxide layer | Aerospace, electronics, consumer products |

| Bead-Blasted Finish | Uniform matte appearance through particle blasting | Medical devices, automotive components |

| Etched Finish | Patterns or text created through chemical/laser etching | Branding, labeling, personalization |

| Powder Coated Finish | Durable and decorative coating application | Outdoor components, machinery parts |

| Painted Finish | Various colors and textures applied with paint | Custom color requirements, artistic applications |

Aerospace leverages simultaneous 5 axis CNC machining to produce strong, lightweight structural components and housings with optimized geometries. The technology also enables engraving and texturing of surfaces for improved performance.

Automotive design complexity demands 5 axis CNC machining for components like precision engine valves, contoured wheels, and optimized fuel injector nozzles with intricately sculpted surfaces to improve power, efficiency, and aesthetics.

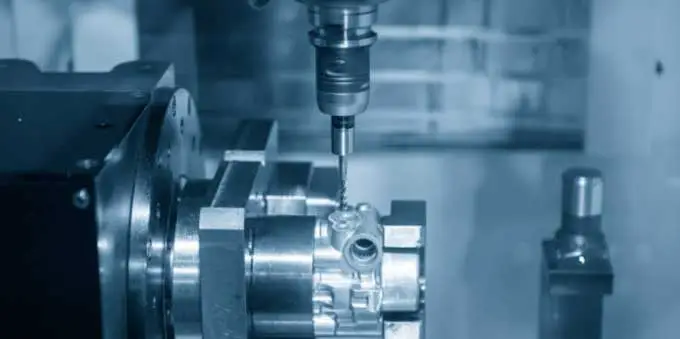

The 5-axes of machining refer to the 3 linear axes (X, Y, Z) plus 2 rotary axes (A, B) that enable full, simultaneous contouring and positioning.

5-axis machines are used to manufacture complex, contoured parts with intricate geometries and deep concavities that require tool access from multiple orientations.

The key difference between 5 and 6 axis machines is the addition of a secondary rotary axis in 6 axis machining, allowing for even more complex part geometries.

Maximum part sizes for 5-axis CNC machining typically range from small benchtop machines to very large floor models able to accommodate parts over 10 feet, depending on the machine.

You should choose 5-axis CNC machining when you need to produce complex, organic or highly contoured parts with accuracy and repeatability that cannot be achieved with 3-axis mills.