Discover Fine Precision's Injection Molding Service, encompassing metal, plastic, and ceramic injection molding. Achieve intricate designs and high precision for diverse industrial applications.

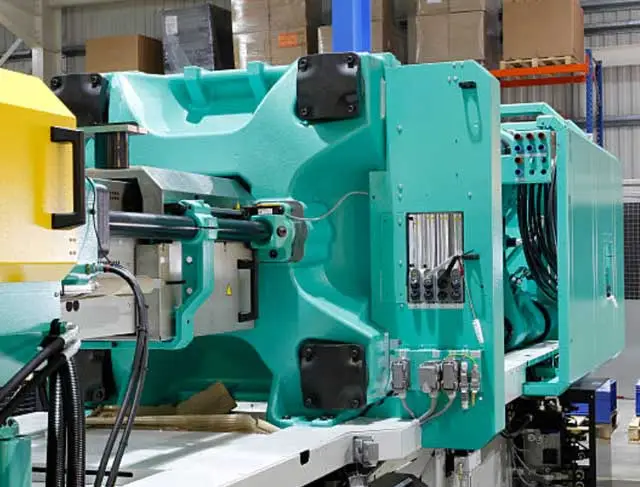

Choose Fine Precision as your premier partner for Injection Molding Services, backed by our extensive expertise in metal, plastic, and ceramic injection molding. With a deep understanding of complex geometries and tight tolerances, we deliver components of exceptional quality and precision. Our state-of-the-art facilities house advanced machinery, enabling us to tackle diverse projects with efficiency and accuracy. From automotive to electronics, our track record spans various industries, showcasing our ability to tailor solutions to unique requirements. Fine Precision's commitment to innovation, quality, and timely delivery ensures your project's success. Rely on us for cost-effective, reliable, and top-notch injection molding solutions that elevate your products to new heights of performance and sophistication.

Explore the diverse classes of injection molding molds at Fine Precision, from prototypes to high-volume production and specialized designs. Discover the optimal mold class for your project's complexity and production needs.

| Mold Class | Description | Suitable For |

| Prototype Molds | Simple and cost-effective molds for initial design testing and low-volume production. | Iterative design, short runs, testing |

| Low-Volume Production Molds | Sturdier than prototypes, for small-scale production with improved durability. | Small production batches, short runs |

| Production Molds | Precision molds built for high-volume, long-term production, ensuring consistent quality. | Large-scale manufacturing, consistent quality |

| Multi-Cavity Molds | Feature multiple cavities to produce multiple identical parts in each molding cycle. | High production output, reduced unit costs |

| Hot Runner Molds | Equipped with heated manifold to maintain material temperature, reducing waste and enhancing efficiency. | Efficient material usage, reduced waste |

| Family Molds | Capable of producing different parts simultaneously, optimizing efficiency for varied components. | Multiple parts in one cycle, diverse applications |

| Insert Molds | Incorporate pre-made components like metal inserts for added functionality or reinforcement. | Enhancing part strength or function |

| Stack Molds | Utilize multiple mold layers to produce various parts in a single molding cycle. | Complex parts or multiple variations |