3D printed molds can be produced in days versus weeks for conventional machined molds, enabling rapid molded part iterations and production.

Complex geometries like overhangs and undercuts are easily 3D printed in molds without expensive CNC programming or electrodes.

Printing prototype and low-volume molds is drastically cheaper than machined aluminum or steel injection molds that can cost tens of thousands.

Rapid molded plastic parts can leverage finishing options including spray painting, laser etching, pad printing, heat staking, ultrasonic welding, and more to enhance aesthetics and functionality.

Normally, Fine Precision mostly uses plastic materials to make the initial prototypes. The following are commonly used surface treatments for rapid prototypes.

Painting and coating plastic parts offer endless color, texture, and protection possibilities. We provide expert painting and coating services, ensuring the finish adheres well to the plastic substrate. Paints and coatings provide color customization and add a protective layer that can enhance resistance to wear, chemicals, and UV radiation.

Laser etching and engraving are precision surface finishing techniques used for marking and branding metal parts. These processes offer high precision, enabling the creation of intricate designs, serial numbers, and logos on components. Laser marking is often used in the aerospace and medical industries for traceability and identification purposes.

Rapid molds enable low volume production of customized brackets, housings, and clips during vehicle development before full production tooling.

Surgical trainers and guides can be quickly molded for procedural practice and device testing before investing in machined molds.

Functional prototypes of new consumer products like wearables, gadgets, and accessories can be molded for ergonomic testing.

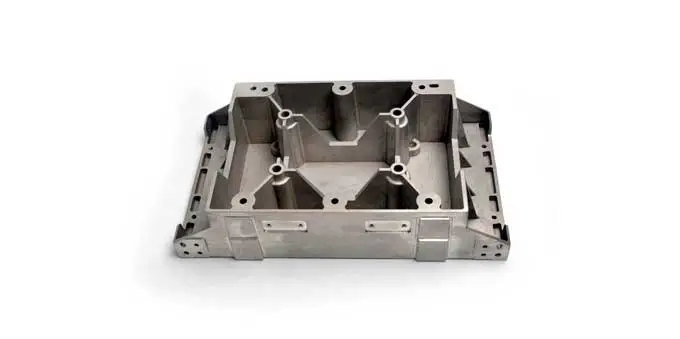

Rapid molding uses 3D printed injection molds to enable fast, affordable low-volume production of plastic parts, combining the speed of additive manufacturing with the consistency of injection molding.

Three common types of molding are injection molding of thermoplastics, compression molding of thermosets, and blow molding to form hollow plastic parts like bottles and containers.

Molding forces material into a cavity while casting involves pouring material into a mold. Molded parts have uniform wall thickness whereas cast parts often have variations.