Modern press brakes produce precision metal bending with tight tolerances down to ±0.005 in. repeatably. Programmable tooling ensures accuracy and consistency.

Steel cutting and bending can fabricate a high mix of parts in low volume. Quick changeovers between parts and bend configurations minimize cost.

The metal's grain structure deforms along the bend contour, maintaining overall strength. Various metals from steel alloys to aluminum can be bent.

Enhance corrosion resistance and appearance of your curving steel components with our variety of metal finishing options including powder coating, electroplating, anodizing and more.

| Treatment | Description | Benefits |

| Powder Coating | Applied colored powder cured into a paint-like coat | Abrasion/corrosion resistant, colorful finishes |

| Anodizing | Electrochemical process produces oxide layer | Corrosion protection, wear resistance |

| Painting | Liquid paint applied and cured | Color/graphics, corrosion/scratch resistance |

| Plating | Electroplated metal coatings | Corrosion protection, conductivity, aesthetics |

| Passivation | Chemical treatment forms inert surface | Enhanced corrosion resistance (stainless steel) |

| Laser Engraving | Laser etches graphics/text into material | Permanent markings for branding, serial numbers |

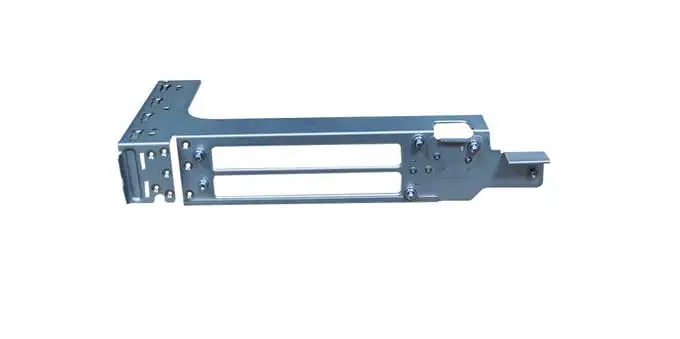

Metal bending forms steel and aluminum for automotive uses like frames, brackets, wheels, and panels to provide strength while minimizing weight.

Titanium and aluminum alloys are bent into lightweight aircraft structures like wings, fuselages, and engine parts.

Stainless steel and titanium are bent into surgical instruments and implants that require high strength and corrosion resistance.

The process of sheet metal bending using a press brake involves positioning and securing the metal within the press brake tool. After alignment, the press descends, applying force to the metal and shaping it into a new form through the creation of angles. Press brakes are capable of exerting forces exceeding 100 tons, allowing them to bend steel sheets with a thickness of over 3 mm.

The bending of metal is referred to as metal bending, forming, pressing, or brake pressing when using a press brake machine.

Metal can be bent using press brakes, tube benders, rollers, or by hand tools like bending forks and bars. Press brakes provide the most precision and control.

The utilization of sheet metal bending is extensive, spanning across industries such as construction, automotive, transportation, aerospace, and infrastructure. It finds application in various sectors to fabricate elements like lips, joggles, flanges, and indents. Additionally, sheet metal bending is occasionally employed to enhance the rigidity of a sheet metal component.