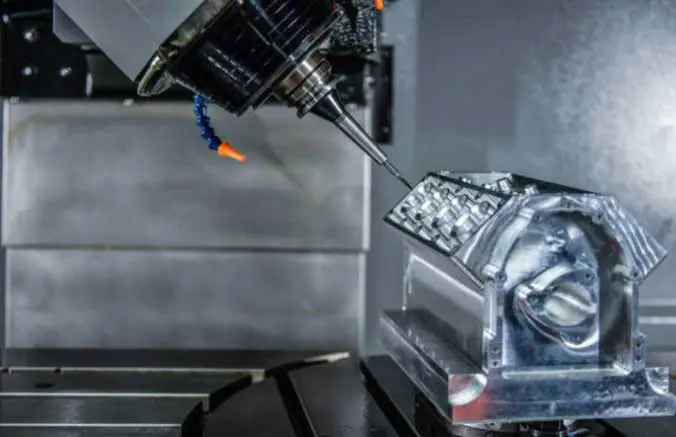

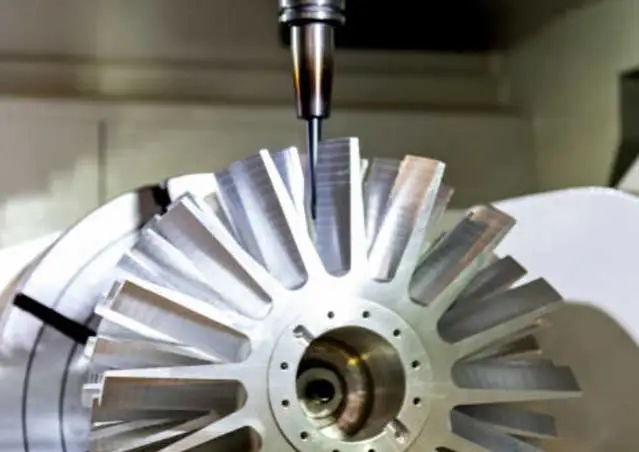

Get strong, lightweight aluminum components with complex geometries machined to perfection through our precision 5 axis CNC services. Our advanced capabilities deliver intricately contoured aluminum parts to meet your exact design needs

Leverage the strength and lightweight properties of aluminum by having your complex components 5 axis CNC machined from 6061, 7075, 2024, or other alloys. Our precision machining delivers contoured aluminum parts made to your specifications.

5052

6061

6063

7075

| Guideline | Description |

| Continuous 5-Axis Movement | Utilize full 5-axis capabilities for complex geometries, reducing tool changes and setups. |

| Avoid Overhangs | Minimize extended tool reach to prevent vibrations, ensuring stability during machining. |

| Proper Fixturing | Design effective fixtures to secure parts during multi-axis machining, minimizing vibrations. |

| Efficient Chip Evacuation | Ensure paths for chips to be easily removed from the cutting area, preventing chip buildup. |

| Tool Access | Consider tool access for all surfaces, optimizing tool paths for intricate features. |

| Minimize Undercuts | Limit undercuts to simplify machining, reducing the risk of tool interference and breakage. |

| Smooth Transitions | Smoothly transition between surfaces to avoid abrupt changes, ensuring consistent cutting. |

| Geometry Simplification | Simplify complex geometries when possible, reducing machining complexity and time. |

| Part Orientation | Optimize part orientation to maximize simultaneous tool engagement, minimizing tool changes. |

| Prototype Testing | Create prototypes to verify design and tool paths, allowing adjustments before full-scale production. |

| Surface Finish | Description | Application |

| Smooth Finish | Clean, polished appearance | Aesthetics, consumer products |

| Matte Finish | Non-reflective, satin-like surface | Functional parts, reduced glare |

| Textured Finish | Patterns or textures for improved grip | Handles, tooling grips |

| Polished Finish | Mirror-like, highly reflective surface | Decorative components, high-end products |

| Brushed Finish | Uniform parallel lines for distinctive look | Decorative components, architectural details |

| Anodized Finish | Colored, corrosion-resistant oxide layer | Aerospace, electronics, consumer products |

| Bead-Blasted Finish | Uniform matte appearance through particle blasting | Medical devices, automotive components |

| Etched Finish | Patterns or text created through chemical/laser etching | Branding, labeling, personalization |

| Powder Coated Finish | Durable and decorative coating application | Outdoor components, machinery parts |

| Painted Finish | Various colors and textures applied with paint | Custom color requirements, artistic applications |

5 axis machining enables high precision manufacturing of components across aerospace, automotive, mold and die, medical, and electronics industries. Typical applications include production of turbine blades, engine components, impellers, prototypes, tooling, surgical instruments, joints, and complex metal parts requiring intricate geometries.